I had my 99 in for service years a go, it went out with a bang. It turned out to be bad capacitors and very much in need of rewiring. It came back with new wiring, the old cloth covered were relaced by black pvc insulated stuff. It has behaved flawlessly since. I think I payed a bit more than your estimated price. To buy the correc type of wires and maybe carbon brushes your self will cost a bit too. A good repair shop has this by the roll and replacement parts in boxes, motor belt, bobbin tyres, etc. It's not always that much to be save by a DIY service. I prefer to do it my self, but I would not hesitate to hand it in some where if the price were right. Here £60 would be a very good price for a service, at least if the repair guy actually did something. All in all, I would say it's worth the price.

I would recommend going through the maintanaces steps of cleaning and oiling before anything else. Chance is it will sort out all the issues you mention. Take the bobbin case out, face plate off, throat plate. There are at least 3 or 4 oil points on top, all hinges and joints behind the face plate and under the base need more than a drop of oil on dry and sticky machines. Don't touch the screw in center near the bobbin case; slide off the bobbin cover completely, the end of the lever is lifted up and towards you; it releases the bobbin case. The race turing under the bobbin case needs a bit of oil too. You need spend some time on each oil point to make enough oil reach inners of joints and hinges. Some places there are tiny holes in the metal, other places the oil points are the joints. Poke the holes on top, to reach all the points behind the stitch length lever (or turn knob) you need to add oil on top of the machine, move stitch length adjustment to extreme positions, test sew and repeat a few times. The same for the hand wheel, it takes more than a few drops of oil to reach the outer part of the hand wheel and the chromed release screw.

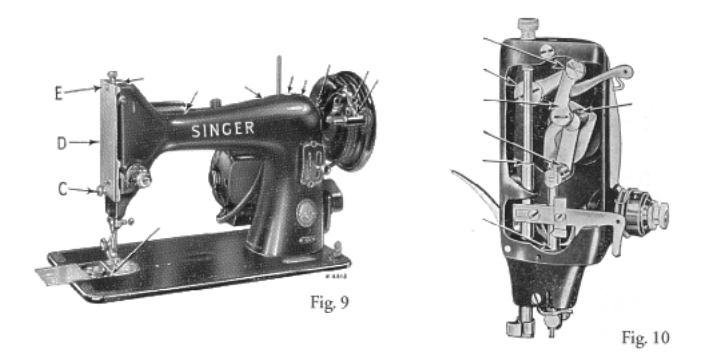

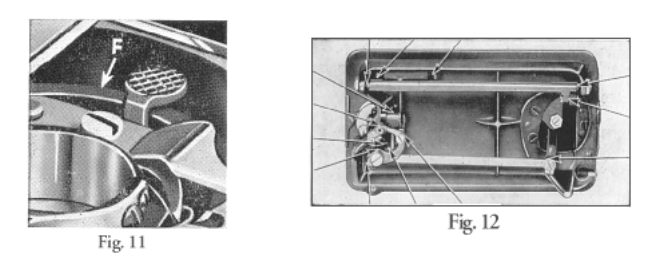

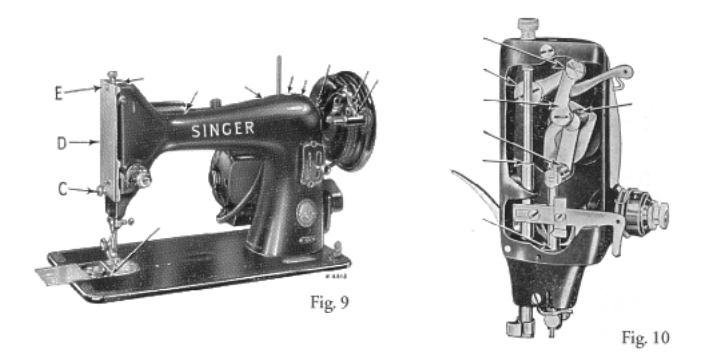

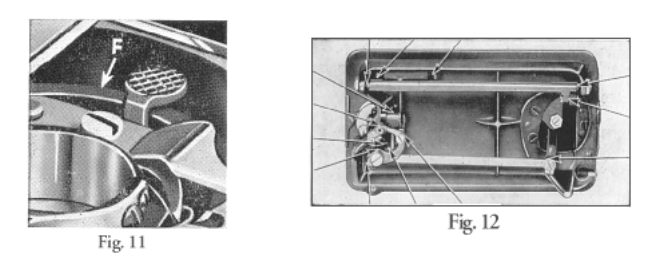

Illustrations showing the oil points. There are similar guides for the top tensioner, the later 99s had a numbered dial, the earlier hand a simpler nut and spring adjustment. You can do a drop test for the bobbin case (measure up a 1 oz bag of rice or beans) as an estimation for the bobbin tension, and fine tune from there. There's always a bit of test sewing and adjustment involved.